⚓ Brush Plating for Marine Equipment: A Smarter Way to Repair

Brush Plating for Marine Applications

When it comes to maintaining the integrity and performance of marine equipment, precision, and speed matter. Unplanned downtime can result in significant costs, especially when critical components like hydraulic cylinders, diesel engines, or gearboxes are involved.

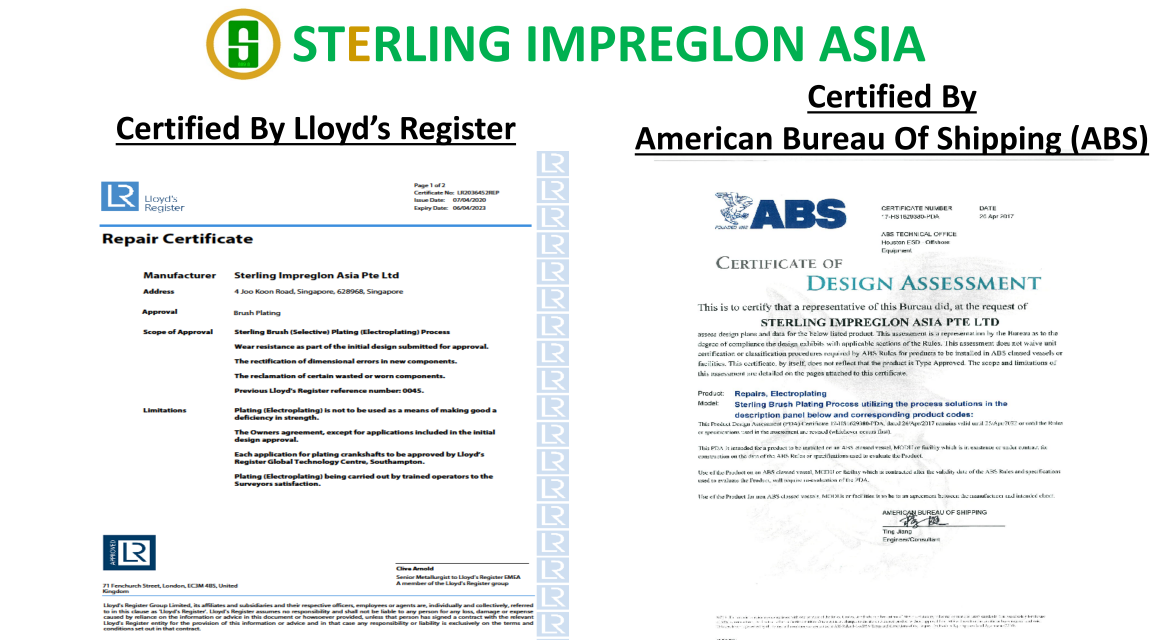

At Sterling Impreglon Asia, our Brush Plating Technology has become a trusted, certified, and class-approved solution for restoring marine components quickly, accurately, and without disassembly.

🛠 Class-Approved and Certified for Confidence

Our proprietary Brush Plating process is proudly:

✅

Class-Approved by Lloyd’s Register

✅

Certified by the American Bureau of Shipping (ABS)

These certifications offer a layer of assurance for shipowners, fleet managers, and marine engineers who seek reliable, approved repair methods for critical equipment—whether dockside or at sea.

🔧 Common Marine Applications

Brush Plating is used extensively in repairing a wide range of marine mechanical components, including:

- Hydraulic Cylinders / Rods

- Mooring Winches

- Gearbox Housings

- Diesel Engine Blocks

- Main Bearing Saddles

- Generators

- Motor Housings & Casings

- Pumps & Valves

⚙️ Typical Damage We Repair

Whether caused by harsh marine environments or mechanical fatigue, we routinely restore components affected by:

- Corrosion Pitting

- Scorelines

- Fretting

- General Wear and Tear

🔩 Why Brush Plating is the Smarter Choice

Unlike traditional repair methods like welding or hard chrome plating, Brush Plating offers several distinct advantages that make it ideal for marine use:

✅

In-Situ Repair (On-Site) – No need to remove large or heavy components

✅

Selective Plating – Only the damaged area is repaired

✅

Cold Process – No heat distortion to the base metal

✅

Time & Cost Efficient – Less downtime, no transport or reinstallation costs

✅

Excellent Adhesion – Strong, long-lasting bond

💡 Beyond Marine: Versatile for Other Industries Too

While Brush Plating is proven in marine environments, the same technology is equally effective in

heavy equipment,

construction, and

power generation industries—restoring everything from hydraulic rods and motor shafts to bearing housings and more.

📩 Ready to Extend the Life of Your Equipment?

Our Brush Plating system offers the perfect balance of speed, precision, and reliability for marine and industrial repairs. Whether you need our repair services or want to own the Brush Plating Set for in-house maintenance, we are here to help.

👉 Contact us today to find out how we can support your operations—dockside or onboard.

#BrushPlating #MarineRepair #OnsiteRepair #HydraulicRepair #MarineEngineering #SterlingImpreglonAsia #ABSApproved #LloydsRegister #IndustrialRepair #DieselEngineRepair #ShipMaintenance #SelectivePlating #HeavyEquipmentRepair