Printing Cylinder Repair

On-Site Brush Plating Repair of a Printing Cylinder

Recently, Sterling Impreglon Asia was called in by a renowned international printing company to repair one of their key production cylinders. This critical component, essential for maintaining high-quality print output, had sustained serious surface damage—deep dents, score lines, and pitting that threatened to disrupt printing accuracy and consistency.

For any printing operation, even a minor defect on a cylinder surface can lead to

wasted material, blurred impressions, and costly downtime. In this case, the damage was too severe for simple polishing or touch-ups. The company needed a

precise, durable, and on-site solution—and that is where our Brush Plating expertise came in.

Assessing the Damage

Upon inspection, multiple defects were identified:

- Deep mechanical dents caused by foreign objects striking the cylinder.

- Scorelines and surface indentations that would have affected print quality.

- Localized wear spots requiring build-up back to original tolerance.

Traditional methods would require dismantling the heavy cylinder and shipping it back to a workshop for extensive machining or replacement—a costly and time-consuming option.

The Brush Plating Repair Process

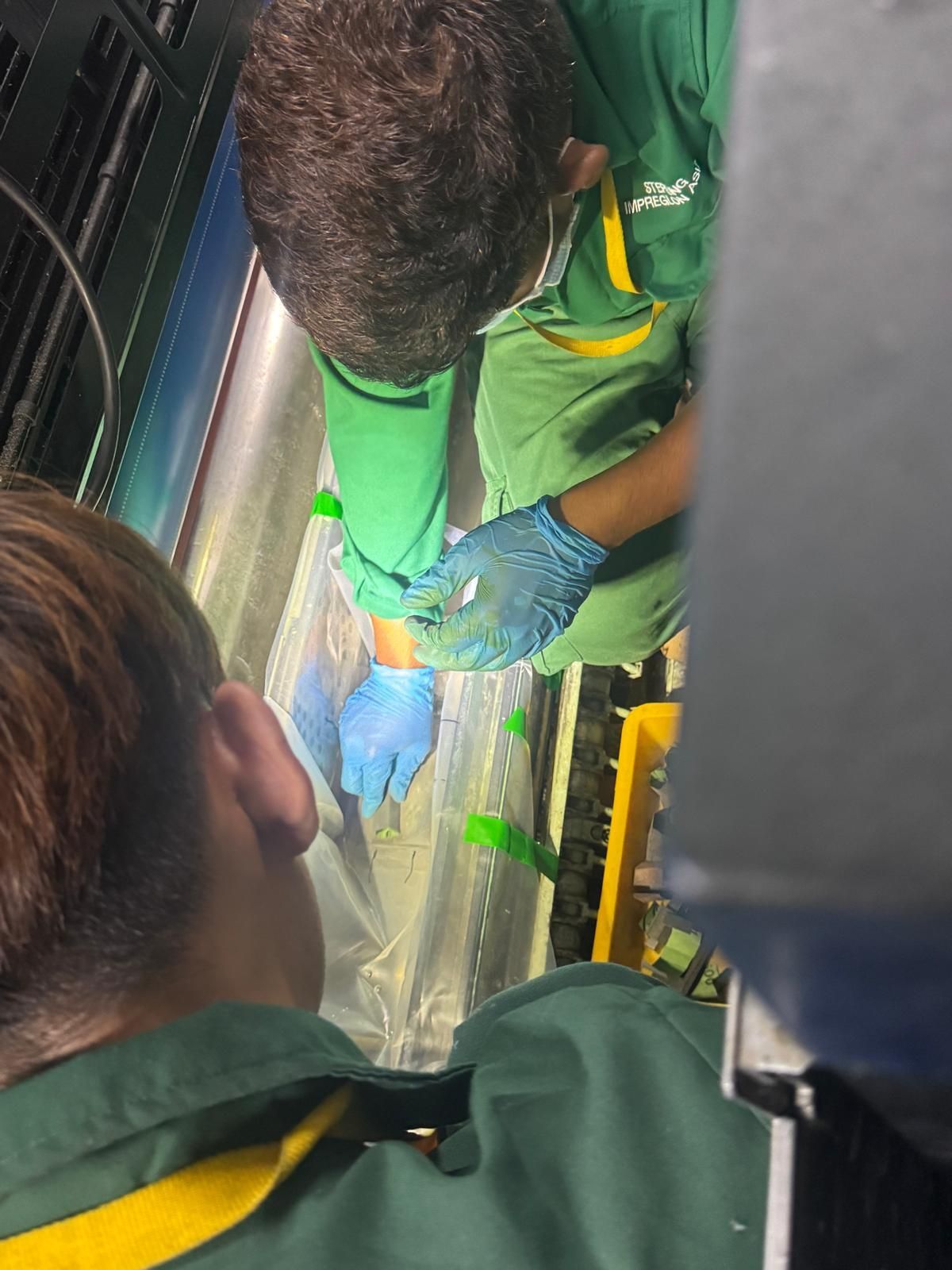

Using our proprietary Brush Plating system, Sterling Impreglon Asia performed the repair directly on-site, without removing the cylinder from the printing machine.

The repair procedure included:

- Damage Marking & Preparation – Each defect area was inspected, marked, and prepared by cleaning and surface activation to ensure strong adhesion.

- Masking & Containment – Protective barriers were applied to isolate the damaged zones and prevent overspill, ensuring precision plating.

- Copper Brush Plating Build-Up – Using controlled electrochemical deposition, layers of copper were applied directly onto the damaged spots. This allowed us to build the surface back to its original profile with micron-level accuracy.

- Finishing & Blending – Once the plating reached the required thickness, the repaired areas were polished and blended seamlessly into the surrounding surface. Nickel capping was applied to ensure the repaired area looks as good as brand new.

Results Achieved

- Minimal Downtime – Repairs were completed on-site, eliminating the need for transport and reinstallation.

- Cost Savings – The customer avoided the high cost of replacing the cylinder or outsourcing machining repairs.

- Restored Precision – The repaired cylinder surface met the dimensional and surface finish standards required for high-quality printing.

- Durable Solution – Our Brush Plating ensures excellent adhesion and long-term performance under operational loads.

A Reliable Partner for Industrial Repairs

This case is a testament to the versatility of Sterling Impreglon Asia’s Brush Plating process. Whether for the printing industry, marine equipment, oil & gas components, or heavy machinery, our technology provides a cost-effective, time-saving, and durable repair solution—keeping critical assets in operation and extending their service life.

👉 If your operations face similar challenges with damaged cylinders or mechanical components, contact Sterling Impreglon Asia today. We bring the workshop to you—with precision, efficiency, and proven results.