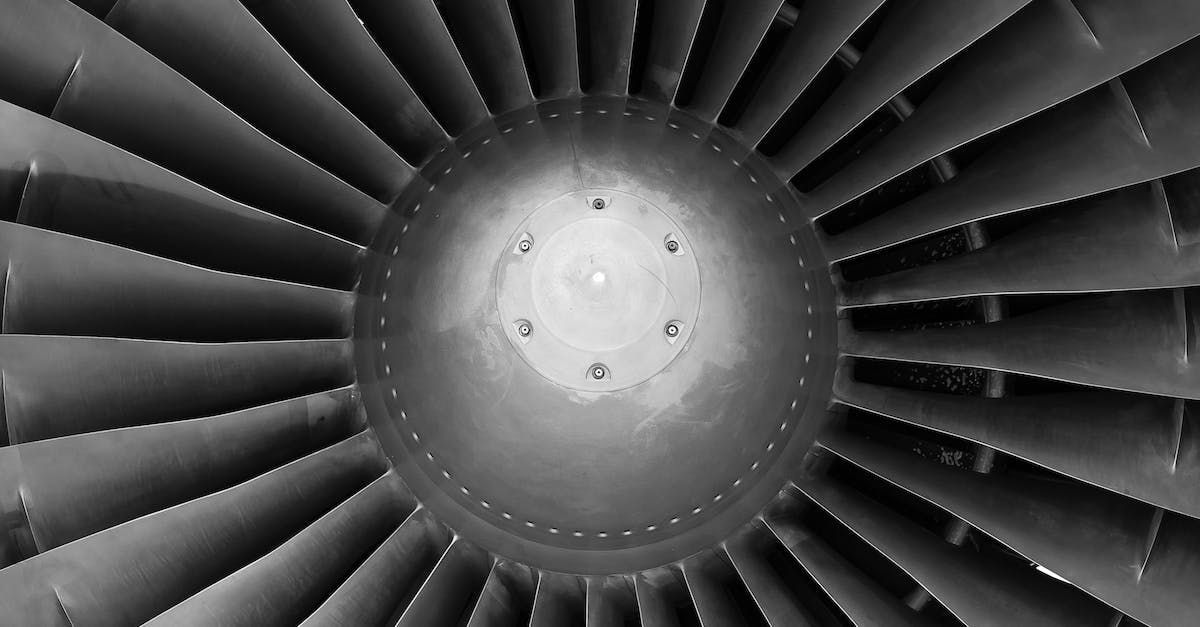

Aerospace Industry

Brush Plating is not commonly known in the aerospace industry but it has a huge advantage in MRO applications compared to tank electroplating. Furthermore, the use of brush plating to apply surface treatments on OEM components help save valuable time and cost.

Common Application for the Aerospace Industry

Types of Surface Treatments in the Aerospace Industry

Corrosion Protection

Our Brush Plating techniques create a protective layer on the components, safeguarding them from harsh Troposphere environment and reducing risk of corrosion.

Wear Resistance

Brush Plating enhance wear resistance to critical parts, increasing their durability and reducing the need for frequent replacements.

Dimensional Restoration

With precision brush plating, we can restore worn-out components to their original dimensions and specifications, saving costs and resources.

Pre-Braze

Brush Plating ensures a molecular bond, providing superior wetting of surfaces, offering a faster, more consistent, and cost effective alternative to traditional methods.