Repairing a Crane's Gearbox Bearing Saddle

Reviving Efficiency: Repairing a Crane's Gearbox Bearing Saddle with Precision Brush Plating

At Sterling Impreglon Asia, we believe in not just fixing mechanical components but restoring them to their optimal performance. In a recent challenging task, we were summoned to address a crane's reduction gearbox bearing saddle damaged by frettings. Here is a glimpse into our meticulous repair process:

The Challenge:

The reduction gearbox bearing saddle, a critical component in the crane's operation, had fallen victim to fretting damage. This not only compromised its efficiency but also posed a potential threat to the entire system's functionality.

Our Expert Approach:

1. Preparation: Before initiating the plating process, our skilled technicians meticulously masked off the targeted area to ensure precision.

2. Grinding: Fretting areas were carefully ground open, widening but not deepening the damaged regions in readiness for the plating procedure.

3. Cleaning: Thorough rinsing and scrubbing followed to eliminate any impurities, providing a pristine surface for plating.

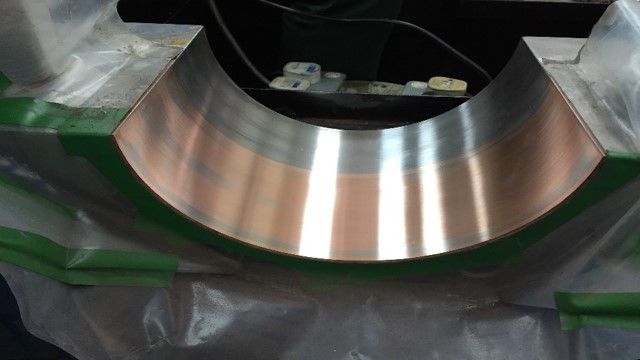

4. Brush Copper Plating: The damaged areas underwent a transformation with our advanced Sterling Brush Copper Plating technique, rebuilding and reinforcing with precision.

5. Smoothing: The plated regions were expertly blended down to seamlessly integrate with the surrounding area, ensuring a flawless finish.

6. Nickel Capping: A final touch of nickel capping was applied to guarantee not just functionality but also an aesthetic restoration.

7. Dimensional Check: Our commitment to quality was underlined by a comprehensive dimensional check, ensuring the plated area met stringent specifications and tolerances set by our customer.

The Result:

What was once a fretting-ridden component emerged as a testament to the restorative power of Brush Plating. The reduction gearbox bearing saddle not only regained its original condition but also surpassed it in terms of durability and longevity.

Why Choose Sterling Impreglon Asia:

- Precision and Expertise: Decades of industry experience translate into precision and expertise in every task.

- Cutting-Edge Technology: Our advanced Brush Plating techniques lead the industry, ensuring unparalleled results.

- Global Trust: Sterling Impreglon Asia is a globally recognized name, synonymous with reliability and excellence.

- Cost-Effective Solutions: Opting for our services means choosing cost-effective alternatives to component replacement.