How a Microscopic Copper Layer Prevents Massive Downtime

The Science Behind Anti-Galling Brush Plating for OCTG

In oilfield operations, the integrity of OCTG (Oil Country Tubular Goods) connections is non-negotiable. Every thread engagement must be precise, smooth, and reliable—especially under extreme torque and pressure. But one persistent issue continues to plague both premium and non-premium connections: galling.

Galling occurs when metal threads rub under pressure, causing adhesive wear, scoring, and surface tearing. It can damage expensive connections and disrupt critical operations.

🔬 How Brush Copper Plating Prevents Galling

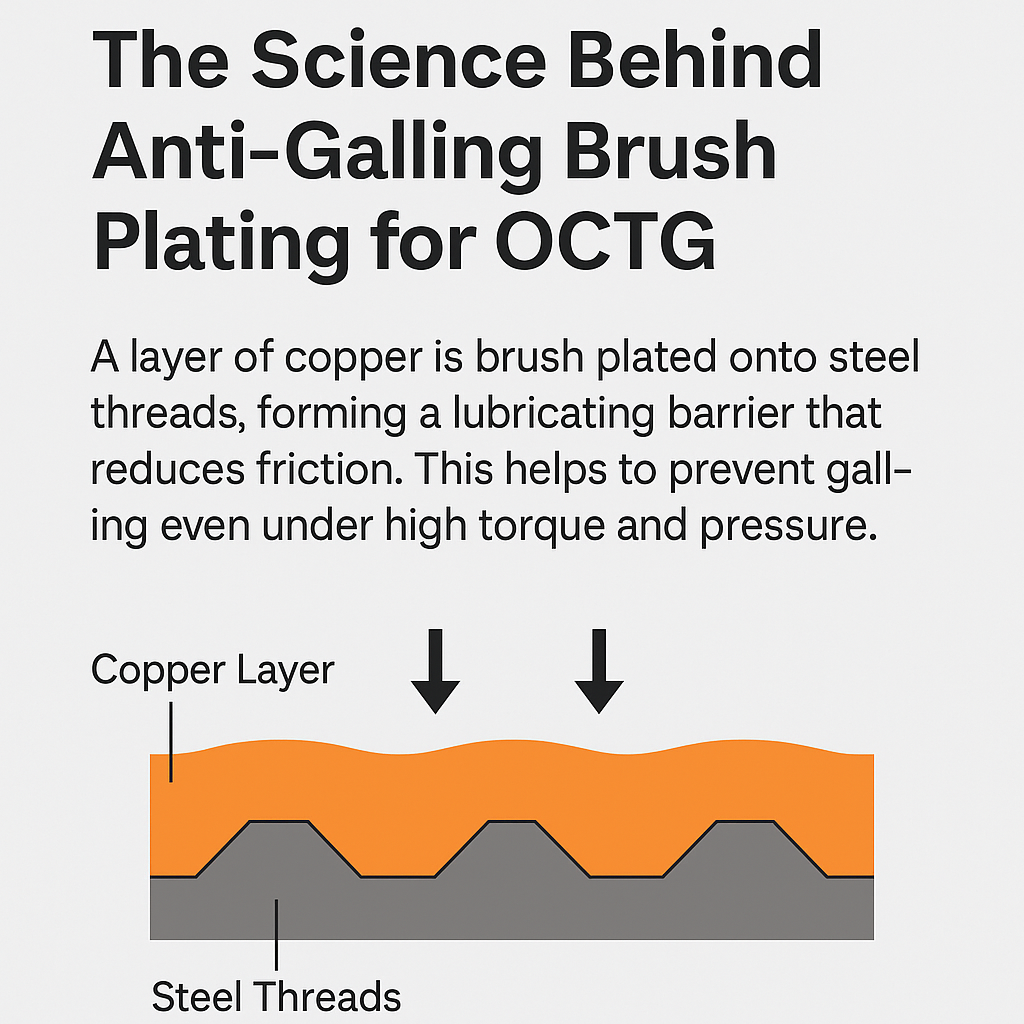

Brush Plating deposits a precise, localized layer of pure copper onto steel threads. This soft, ductile layer:

- Acts as a lubricating barrier between mating threads

- Absorbs surface friction, preventing metal-to-metal adhesion

- Provides reliable anti-galling protection, even under high torque

- Supports repeated make-and-break cycles without damaging the threads

Even in harsh environments, copper remains stable, helping maintain thread geometry and sealing performance.

🧪 Field-Tested for the Oil & Gas Industry

Sterling Impreglon Asia’s process is qualified and trusted by major OCTG manufacturers including VAM, JFE, Tenaris, API, and more. We validate every job with:

- Adhesion tape testing

- High-pressure water jet tests (up to 132,000 PSI)

- Microscopic inspection for bond integrity and thickness

⚙️ Visual: How It Works

[See image above]

💡 Better Protection Starts at the Surface

With Brush Copper Plating, galling becomes a thing of the past. Whether you are qualifying a premium thread or extending the life of non-premium accessories, our plating delivers unmatched adhesion, durability, and anti-galling performance.

📩 Get in touch with Sterling Impreglon Asia today to learn more about our copper Brush Plating solutions for OCTG.